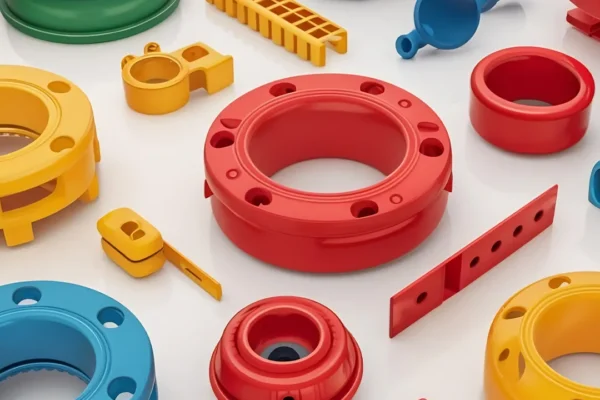

Innovative Plastic & Rubber Moulding Techniques

In today’s fast-paced manufacturing industry, plastic and rubber moulding play a crucial role in producing high-quality components with precision and efficiency. As businesses seek durable, cost-effective, and customized solutions, advanced moulding techniques are transforming the way products are developed. At Arista Polymers, we specialize in cutting-edge plastic and rubber moulding services, ensuring superior quality, accuracy, and innovation in every product we create.

Advanced Techniques in Plastic Moulding:

Plastic moulding has evolved significantly with modern technology and automation, allowing manufacturers to produce intricate designs with minimal waste. Some of the most innovative plastic moulding techniques include:

- Injection Moulding - A widely used process that injects molten plastic into a mould, producing highly detailed and consistent parts with excellent strength.

- Blow Moulding – Ideal for creating hollow plastic products such as bottles and containers with uniform wall thickness.

- Rotational Moulding – Best for manufacturing large, durable parts like tanks and industrial containers with seamless construction.

- Thermoforming – A process that heats a plastic sheet and shapes it into precise forms, perfect for packaging and consumer products.

These techniques not only enhance efficiency and cost-effectiveness but also enable the development of customized, lightweight, and durable plastic components tailored to industry needs.

Revolutionary Rubber Moulding Methods:

Rubber moulding is essential for industries requiring high-flexibility, shock absorption, and chemical resistance. At Arista Polymers, we utilize innovative rubber moulding techniques such as:

- Compression Moulding - A cost-effective method where rubber material is compressed into a mould, perfect for seals, gaskets, and O-rings.

- Injection Rubber Moulding – This process offers high precision and repeatability, making it ideal for complex rubber components in the automotive and aerospace industries.

- Transfer Moulding – A technique that allows for greater design flexibility, especially for rubber parts requiring embedded metal inserts.

- Liquid Silicone Rubber (LSR) Moulding– Used for medical and high-temperature applications, ensuring excellent durability and biocompatibility.

With these innovative techniques, manufacturers can achieve high-performance rubber products with superior elasticity, strength, and weather resistance.

Why Choose Arista Polymers for Your Moulding Needs?

At Arista Polymers, we stay ahead of the curve by leveraging state-of-the-art moulding technologies to meet the evolving demands of various industries. Whether you require precision plastic components or high-quality rubber parts, we offer custom solutions, fast turnaround times, and unmatched expertise in the field.

LOOKING FOR TOP-TIER PLASTIC AND

RUBBER MOULDING SERVICES?

Contact Arista Polymers today and

bring your designs to life with cutting-edge innovation!

Author